How to cut galvanized steel pipe?

When the galvanized pipe is cut off, deformation, unevenness of the cut and cracking of the cut occur. How does it work? Today galvanized pipe manufacturers to introduce you, galvanized pipe cutting operation to pay attention to some of the issues, after reading if the correct operation will make galvanized pipe-cutting work very smoothly.

When cutting galvanized pipes, it is very important to choose the right cutting tool. You can choose different cutting methods such as mechanical cutting, spark cutting, water cutting, etc. The specific choice needs to be based on the diameter of the cut pipe (for large diameter pipe, you can use mechanical cutting or water cutting, etc., for small diameter pipe you can use manual cutting or spark cutting, etc.), wall thickness and cutting quality requirements.), wall thickness and cutting quality requirements to decide.

How to cut galvanized pipes properly? Here’s What You Need to Know to Do It Right

Selection and preparation of cutting tools: Select the appropriate cutting tool according to the size and requirements of the pipe to be cut. The cutting tools need to be checked and calibrated before cutting to ensure that the cutting tools have sharp edges, accurate cutting positions and correct cutting directions.

Selection of cutting position and mode: The cutting position and mode need to be determined before cutting to avoid distortion or deformation during the cutting process.

Control of cutting depth and speed: The cutting depth and speed need to be controlled during the cutting process to ensure the effect and quality of cutting. Too fast cutting speed will easily lead to serious burrs at the cutting mouth, while too slow cutting speed will affect the cutting efficiency and quality.

Treatment after cutting: After the cutting is completed, the cutting mouth needs to be treated to remove the burrs and impurities at the cutting edge.

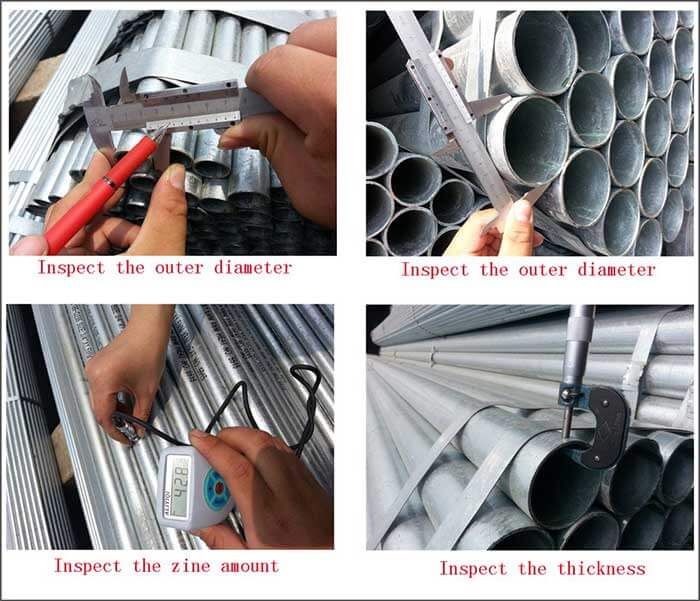

Inspection and testing: After the cutting is completed, the quality of the cut needs to be inspected and tested to ensure that the cutting effect meets the requirements. Measuring tools and instruments can be used to check the cutting surface and pipe diameter to ensure that the cutting quality meets the expected requirements.

Best tool to cut galvanized pipe?

- Pipe cutter: A pipe cutter is a hand-held tool that uses a sharp wheel to cut through pipes. It’s a great option for cutting galvanized pipes up to 2 inches in diameter. Pipe cutters are easy to use and produce clean, straight cuts.

- Hacksaw: A hacksaw is a manual saw with a fine-toothed blade that can be used to cut through galvanized pipes up to 6 inches in diameter. This option requires more effort than a pipe cutter and may produce slightly rougher edges.

- Reciprocating saw: A reciprocating saw is a power tool that can be used to cut through galvanized pipes up to 12 inches in diameter. It’s a good option for cutting pipes in tight spaces or at awkward angles.

- Angle grinder: An angle grinder is a power tool that uses a rotating disc to cut through metal. It’s a good option for cutting thick galvanized pipes or making precise cuts. However, it can be difficult to control and may produce more sparks than other cutting tools.

How to cut 2 inch galvanized pipe?

- Using a pipe cutter:

- Secure the pipe cutter around the pipe at the point where you want to make the cut.

- Tighten the cutter and rotate it around the pipe several times, tightening it a little more with each rotation until the pipe is cut through.

- Use a deburring tool or sandpaper to smooth out any rough edges on the cut end of the pipe.

- Using a hacksaw:

- Mark the pipe at the point where you want to make the cut.

- Hold the pipe steady and saw through it using a back-and-forth motion with the hacksaw.

- Use a deburring tool or sandpaper to smooth out any rough edges on the cut end of the pipe.

- Using an angle grinder:

- Secure the pipe in a vice or clamp to hold it steady.

- Use an angle grinder with a cutting wheel to make a straight cut through the pipe.

- Use a deburring tool or sandpaper to smooth out any rough edges on the cut end of the pipe.

How to speed up the galvanized pipe cutting efficiency?

Use automated cutting equipment: Using automated cutting equipment can greatly improve cutting efficiency. For example, using laser cutting equipment can be tens of times faster than using manual cutting equipment. In terms of efficiency, originally a galvanized pipe was cut into many small tubes, and it took about 15 seconds for a saw blade to cut a section. Now it takes less than 2 seconds to complete the laser cutting, which is nearly 10 times more efficient. Traditional saw blades are cut about 1,000 times each time, the saw blade wears badly and needs to be replaced, which costs several hundred dollars a time. And laser cutting is a non-contact cutting, compared to the traditional saw blade cutting cost savings.

How does TYTSTEEL galvanized pipe factory from China cut galvanized pipes?

Are you wondering how Chinese factories cut steel pipe products? At TYT STEEL, a professional and leading steel supplier in China, we have the expertise and experience to process various steel pipes to almost any specification. Equipped with state-of-the-art processing equipment, we ensure 100% satisfaction for our clients. Contact us today to learn more about our steel-cutting technology and how we can meet your steel pipe needs.

How to avoid deformation, unevenness of the cut and cracking of the cut when cutting steel pipes?

1. To cut off the place, please use a rag or soft cloth to wipe the surface of galvanized pipe completely clean of oil, debris or mud.

2. Be sure to select the special galvanized pipe cutting.

3. The location of the cut-off should be determined by drawing the location and marking the cut-off line with a meter ruler or other measuring tool in accordance with the construction drawings and site conditions.

4. When cutting off, please use a vise and other galvanized pipe fixing apparatus to make sure it is fixed before cutting.

5. Excessive cutting pressure will lead to pipe warping and inequality in the cut. In the cutting process, according to the material and thickness of the pipe, adjust the cutting speed appropriately to minimize the thermal impact of cutting.

6. The cutting surface of the galvanized pipe should be kept true round and the cutting line should be at right angles to the axis of the galvanized pipe. Excessive force is the cause of cutting galvanized pipe into flat or oval, so the galvanized pipe should be cut with proper force.

7. Strengthen cooling measures to make the cutting part cool down quickly to reduce thermal deformation and thermal cracking.

8. Cut off the surface of the iron chips, burrs should be completely removed with a file or appropriate tools to prevent iron chips, burrs in the insertion of the other parts of the joint scratch rubber o-ring and other appurtenances.

Cutting of Galvanized Steel Pipe Deep Processing Line.

We have sufficient steel pipe stock reserve, this video shows the cutting process of pre-galvanized steel pipe, furniture black back pipe, hot-dip galvanized steel pipes and other products, we can clearly see that steel pipes are so smoothly and non-burr tube end after cutting, high precision. If you have any cutting processing needs , please feel free to contact us , steel pipes can be cut in different lengths according to customer requirements.