Hi, I’m max. As time advances, steel tubes play an indispensable role in modern engineering as the cornerstone of construction and infrastructure. In this world of steel, we know how to give tubes elegant lines with bending and how to drill holes with precision to give them function and soul. Painting gives tubes their brilliant colors, and shrinking makes connections strong and seamless. Meanwhile, threading allows the screws and tubes to blend together in perfect harmony, building a solid foundation for the project.

In this article, we step into the realm of bending, drilling, painting, shrinking and threading to get a glimpse of how these key processes are utilized in the production of steel tubing. Let me give you a detailed overview of each process!

1. bending galvanized pipe

1.1 how to bend galvanized steel pipe?

Bending is the process of bending a steel pipe by mechanical or hydraulic equipment to make it into a desired angle or curvature. Bending is usually used to make curved shaped steel pipes, such as pipe galvanized steel pipe elbow and bends.

1.1.1bending galvanized steel pipe operation process

| Place the steel pipe to be bent on the galvanized pipe bender and adjust the clamping device of the bending machine bed to ensure that the pipe is stable. |

| Set the bending angle and bending radius as needed, and adjust the equipment using either a robot or a manually operated controller. |

| Turn on the hydraulic system or start the mechanical device to apply appropriate pressure and force to gradually bend the steel pipe into the desired shape. |

| Depending on the specific bending requirements, it may be necessary to make several bends until the steel pipe reaches the desired angle or shape. |

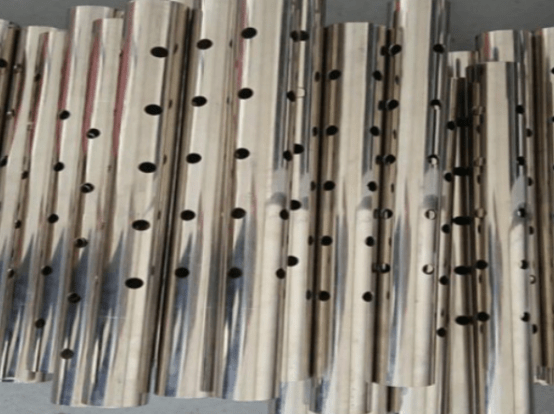

2. drilling galvanized pipe

2.1 how to drill a hole in galvanized pipe

Drilling is the process of drilling holes in galvanised pipe, usually by means of a drilling machine or punch press.

2.1.1 drilling into galvanised pipe procedure

| Adjust the position and angle of the drill bit as required to ensure the hole is in the correct position and direction. |

| Start the drilling machine so that the drill bit rotates and gradually drills into the surface of the steel pipe. |

| Control the depth and diameter of the drilled holes to ensure that the design requirements are met. |

| After drilling is completed, clean the holes and check their quality to ensure that they are free of splinters and cracks and that they meet the requirements. |

3. painting galvanized pipe

3.1 can you paint galvanized pipe?

Yes, it can be painted. Paint spraying is the process of spraying a layer of paint on the surface of a steel pipe to improve its anticorrosive properties of the necessary operations

3.1.1 how to clean galvanized pipe before painting

Use a wire brush or steel wool to gently scrub the surface of the galvanized pipe, removing any loose dirt, rust, or debris. Be careful not to scratch the galvanized coating.

Rinse the galvanized pipe thoroughly with clean water to remove any detergent or degreaser residue.

Allow the pipe to air dry completely before moving on to the next step.

If the galvanized surface has a glossy finish or appears too smooth, you may consider lightly sanding it with fine-grit sandpaper. This will help improve paint adhesion.

3.2.1 spray paint for galvanised pipe spray paint operation process:

| Clean the surface of the steel pipe to remove dust, oil and other impurities, refer to 3.1.1. |

| Pour the paint into the spray container of the spraying equipment and adjust the spray pressure and nozzle size of the spraying equipment. |

| Place the steel pipe in the spraying area and evenly spray the paint on the surface of the pipe. |

| Wait for the paint to dry, and if necessary, apply multiple layers of touch-up paint to achieve the desired coating thickness and effect. |

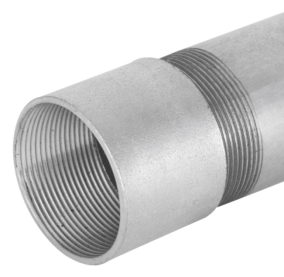

4. threaded galvanized pipe

Threading is the process of machining threads on the outer or inner surface of a steel pipe to facilitate the connection of other threaded components.

4.1 threading galvanised pipe operation process:

| External Threading | Place the pipe on the threading machine and align the thread cutting tool or thread turning tool with the outside surface of the pipe. Then control the feed and rotational speed of the cutting tool to begin machining the threads. |

| Internal threading | The steel pipe is placed inside the threading machine, usually with the help of a thread drill for internal thread machining. The thread drill is activated and the feed rate is controlled to form the required internal threads along the inner surface of the steel pipe. |

4.2 how to connect galvanized pipe without threads?

Threadless galvanised pipes can be connected by flanges (this type of connection is suitable where dismantling and replacement is required), welded connections (this type of connection is very strong and is suitable where higher strength and sealing is required). , casing connections (where the end of one galvanised pipe is fitted into a portion of another galvanised pipe). The pipes should be connected by means of a clamp connection or a glue connection (suitable for smaller diameter pipes).

4.3 how to connect non threaded galvanized pipe to pex?

| Fastening clamp connection | The PEX pipe is secured to the end of the unthreaded galvanised pipe using special fastening clamps for PEX pipe. A special clamping tool is used to securely fasten the clamp to the outer wall of the PEX pipe, ensuring a tight connection between the PEX pipe and the galvanised pipe. Tightening the clamp connection is a quick and reliable method for general household and low pressure applications such as water supply and heating systems. |

| Transition Fitting Connection | Use transition fittings to connect PEX pipe to unthreaded galvanised pipe. Transition fittings usually have a port that fits the PEX pipe at one end and a port that fits the unthreaded galvanised pipe at the other. Apply thread adhesive or sealant to the threaded portion of the fitting and fasten the transition fitting between the PEX pipe and the galvanised pipe to ensure a tight and reliable connection. The transition connection is suitable for special applications, e.g. when it is necessary to connect a PEX pipe to an existing unthreaded galvanised pipe system. |

4.4 how to connect non threaded galvanized pipe to pvc?

| PVC glue connection | Ensure that the end surfaces of the unthreaded galvanised pipe and the PVC pipe are smooth and free of grease, removing any debris. Apply PVC glue or special PVC pipe joining adhesive to the outer surface of the unthreaded galvanised pipe and the inner surface of the PVC pipe. Ensure that the application is even and covers the entire connection area. |

| Transition Fitting Connections | Use transition fittings to connect unthreaded galvanised pipe to PVC pipe. Transition fittings usually have a port that fits the unthreaded galvanised pipe at one end and a port that fits the PVC pipe at the other. Apply thread adhesive or sealant to the threaded portion of the fitting and fasten the transition fitting between the unthreaded galvanised pipe and the PVC pipe to ensure a positive seal. Transition joints are used in special cases, for example, when it is necessary to connect a PVC pipe to an existing threadless galvanised pipe system. |

That’s all I’ve shared today, I hope you find it helpful. If you are also in the construction industry, check out more information about our company:

TYTSTEEL: Your Professional Galvanized Steel Pipe Manufacturer & Supplier

Tianjin Tianyingtai Steel Group Is Located In Jinghai County, Tianjin, is a professional manufacturer of galvanized steel pipes in China. All the pipes are high-frequency welded. It has been experienced for 20 years so far. That’s right, you can rely on us!

There are hot-dip galvanized steel pipes and pre-galvanized steel pipes. We produce both types of galvanized steel pipes according to BS 1387, EN 39, JIS 3444, and ASTM A53/A53M standards. BV or SGS inspection is available if you require.

All of our galvanized steel pipes are tested for mechanical properties after production is completed. The test includes testing the tensile strength, yield strength, elongation, and chemical elements of the galvanized steel pipe to ensure that its mechanical properties meet the standard requirements. It can meet at least 8 hours corrosion free in salt spray test.

Still doubtful? Here are other reasons why we’re your best bet:

We’re expanding fast. We currently have 500+ employees and 80,000 square feet of factory space ready to serve you.

800+ global, happy customers. We’ve made products for firms in Peru, the Philippines, Thailand, Ghana, and more.

We have our own factory and experimental test center to achieve cost and quality control. Connect with us on our site and we’ll get back to you ASAP.

Save 30% on Costs Get Steel Pipes from China Factory