Steel pipe is an absolutely essential material in the whole process of construction site use. With it, you can ensure the quality of the project, improve the project creation conditions, and facilitate the construction site. It can be said that the steel pipe is the “site of the small hands” on the project.

The raw material of steel pipe is steel strip, i.e. commonly speaking steel pipe is made of rolled steel strip.

What SCHEDULE NUMBERS are available?

SCHEDULE NUMBER is given as :

5, 5s, 10, 10s 20, 20s, 30, 40, 40s, 60, 80, 80, 100, 120, 140 and 160.

Schedule Number with “s” is for Stainless Steel pipe.

Schedule Number without “s” is for Wrought Steel pipe.

PIPE WEIGHT is given as :

STD – Standard weight.

XS – Extra strong.

XXS – Double extra strong.

XH-Extra Heavy

XXH – Double Extra Heavv

STD pipe is the lightest type of pipe and is typically used in low-pressure applications such as water and natural gas pipelines.

XS piping is stronger than STD piping and is typically used in applications that require higher pressures, such as fire protection systems.

XXS piping is the strongest type of piping and is typically used in applications that require the highest pressures, such as oil and gas piping.

XH pipe is an older name for extra strong pipe. It is equivalent to XS pipe.

XXH pipe is the older name for double extra-strength pipe. It is the equivalent of XXS pipe.

What is a Schedule 40 Steel Pipe?

We often hear people say Schedule 40 or Schedule 80, but what does that mean?

Schedule 40 steel pipe is made from mild steel, a type of steel known for its strength and corrosion resistance. The wall thickness of this pipe is 40% thicker than standard steel pipe, allowing it to withstand higher pressures.

What are the Benefits of Schedule 40 Steel Pipe?

- One of the advantages of Schedule 40 steel pipe is that it can be galvanized. Galvanizing is a process where a thin layer of zinc is applied to the pipe to help protect it from corrosion. This makes Schedule 40 steel pipe ideal for applications where the pipe is exposed to the elements.

- Schedule 40 steel pipe has a wall thickness that is 40 percent greater than standard steel pipe, making it stronger and able to withstand higher pressures and temperatures.

- Schedule 40 tubing costs less than Schedule 80 tubing, making it a more economical choice in many applications.

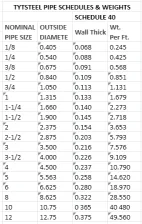

TYTSTEEL PIPE schedule 40 pipe Sizes & WEIGHTS

how thick is schedule 40 pipe? See table

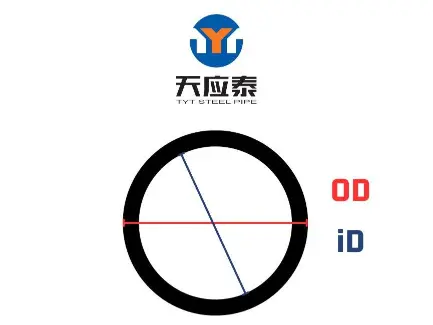

Schedule 40 pipe Id & schedule 40 pipe Od

As you can see, the OD and ID of a pipe are not always the same. The ID is always smaller than the OD.

The OD and ID of a pipe are important considerations when choosing a pipe for a particular application. The OD is important because it determines the physical size of the pipe, and the ID is important because it determines the flow of fluid through the pipe.

If you don’t know how to choose the right steel pipe for your project you can consult our business manager.

Schedule 40 galvanized steel pipe

The wall thickness of Schedule 40 galvanized steel pipe is 0.237 inches (6.02 mm). This makes it thicker than standard steel pipe. Schedule 40 galvanized steel pipe is a good choice for applications where a strong, durable, and corrosion-resistant pipe is needed. It is also a good choice for applications where the pipe will be exposed to the elements.

Schedule 40 pvc pipe

Schedule 40 PVC pipe is a type of polyvinyl chloride (PVC) pipe that is commonly used in plumbing and piping systems. It is a popular choice for cold water and drain-waste-vent (DWV) applications, as well as for some electrical and irrigation applications.

Schedule 40 PVC pipe is available in a variety of sizes, from 1/2 inch to 10 inches in diameter. It is also available in a variety of colors, including white, gray, and black.

Temperature limitations: I wouldn’t suggest using it if hot water will be flowing through it, or if water hammer causes the pipe to move around when the flow starts/stops. Schedule 40 PVC is nowhere near as strong as Schedule 40 steel.

Schedule 40 pipe pressure rating

| Pipe Size | Pressure Rating |

| 1/2 inch | 300 PSI |

| 3/4 inch | 300 PSI |

| 1 inch | 300 PSI |

| 1-1/4 inch | 250 PSI |

| 1-1/2 inch | 200 PSI |

| 2 inch | 150 PSI |

| 2-1/2 inch | 100 PSI |

| 3 inch | 80 PSI |

| 3-1/2 inch | 60 PSI |

| 4 inch | 50 PSI |

| 5 inch | 40 PSI |

| 6 inch | 30 PSI |

| 8 inch | 20 PSI |

| 10 inch | 15 PSI |

| 12 inch | 10 PSI |

| 14 inch | 8 PSI |

| 16 inch | 6 PSI |

| 18 inch | 5 PSI |

| 20 inch | 4 PSI |

| 24 inch | 3 PSI |

The pressure rating of Schedule 40 pipe is an important consideration when choosing a pipe for a particular application. The pipe must be able to withstand the maximum pressure that will be applied to it. Otherwise, it could burst and cause a serious accident.

What is schedule 40 pvc pipe used for?

| Water | Schedule 40 steel pipe is one of the most commonly used pipes in water pipelines. It has good hygienic properties and can guarantee the safety of drinking water for urban residents. |

| Natural Gas & Steam | Natural gas: Schedule 40 steel pipe is mainly used to transport liquefied natural gas, such as city gas supply, industrial gas, etc.. Steam: It is characterized by high strength, corrosion resistance and abrasion resistance, and is suitable for conveying various types of steam, such as industrial steam and boiler steam. |

| Building Structures | Schedule 40 steel pipe is mainly used to manufacture structural parts such as columns, beams and trusses. It has good anti-seismic performance and can guarantee the safety of building structure. |

| Machinery Manufacturing | Schedule 40 steel pipe is mainly used to manufacture shafts, tubes, plates and other parts. It has good processing performance and can meet the manufacturing requirements of mechanical equipment. In the manufacture of equipment pipelines, Schedule 40 steel pipe is mainly used for the manufacture of pipelines for the transportation of liquids and gases. It has good hydrodynamic properties, which can guarantee the normal operation of equipment. |