TYT report:2023.1

What is the common process way of steel pipes? Today I will have a brief introduction for them.

To meet clients’ different demands in the project, TYT company established a one-stop service production line, which can provide deep processing services like bending, drilling, painting, shrinking, and Threading. Saving your production time and money. Here let’s go through them one by one.

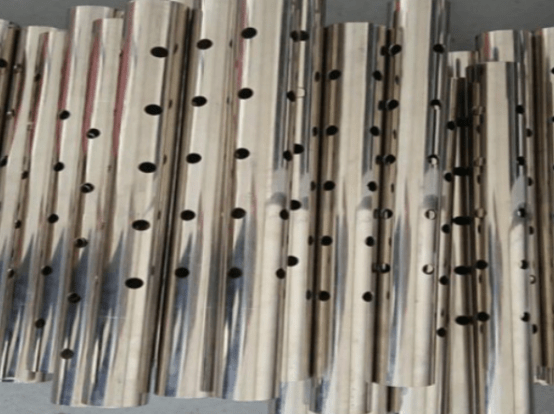

What is Drilling?

The process of laser drilling is an extremely complex thermophysical process of laser-matter interaction. Therefore, there are many factors affecting the quality of laser drilling. To drill high-quality holes, the parameters affecting the quality of drilling should be analyzed and understood according to the general principles and characteristics of laser drilling. These parameters include: laser pulse energy, pulse width, defocus amount, and pulse laser repetition rate.

How do make sure of the quality of drilling?

( 1 ) Applying a positive pressure on the surface of the workpiece or installing a low-pressure chamber on the opposite side of the workpiece can help remove the vaporized material and increase the discharge of the liquid phase during the drilling process.

( 2 ) Install a photoelectric detector in the safe position below the workpiece, which can detect the penetration of the workpiece in time.

( 3 ) Using liquid film or metal platinum to cover the workpiece can reduce the taper of the hole and prevent liquid splash.

( 4 ) To prevent the accumulation of melt in the hole in time, the material whose vaporization temperature is lower than the melting temperature of the processed material can be placed behind the workpiece.

( 5 ) Use a laser as a processing tool to make holes in the workpiece, and then use other methods to achieve the required accuracy. At present, the mechanical processing of diamond sand is generally used, the pore size finishing with a punch and metal wire, chemical corrosion method, and so on.

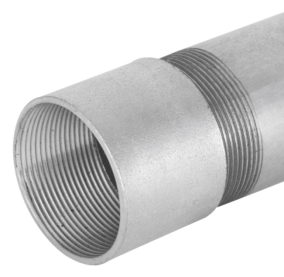

What is threading?

Pipe threading is a kind of deep processing craft. How can we guarantee the quality of threading?

The faster the rotation speed of the steel pipe turning tool, the higher its concentricity, and the smoother the milling surface. Therefore, when the internal thread is milled, the surface of the thread is smooth and there is no iron residue left.